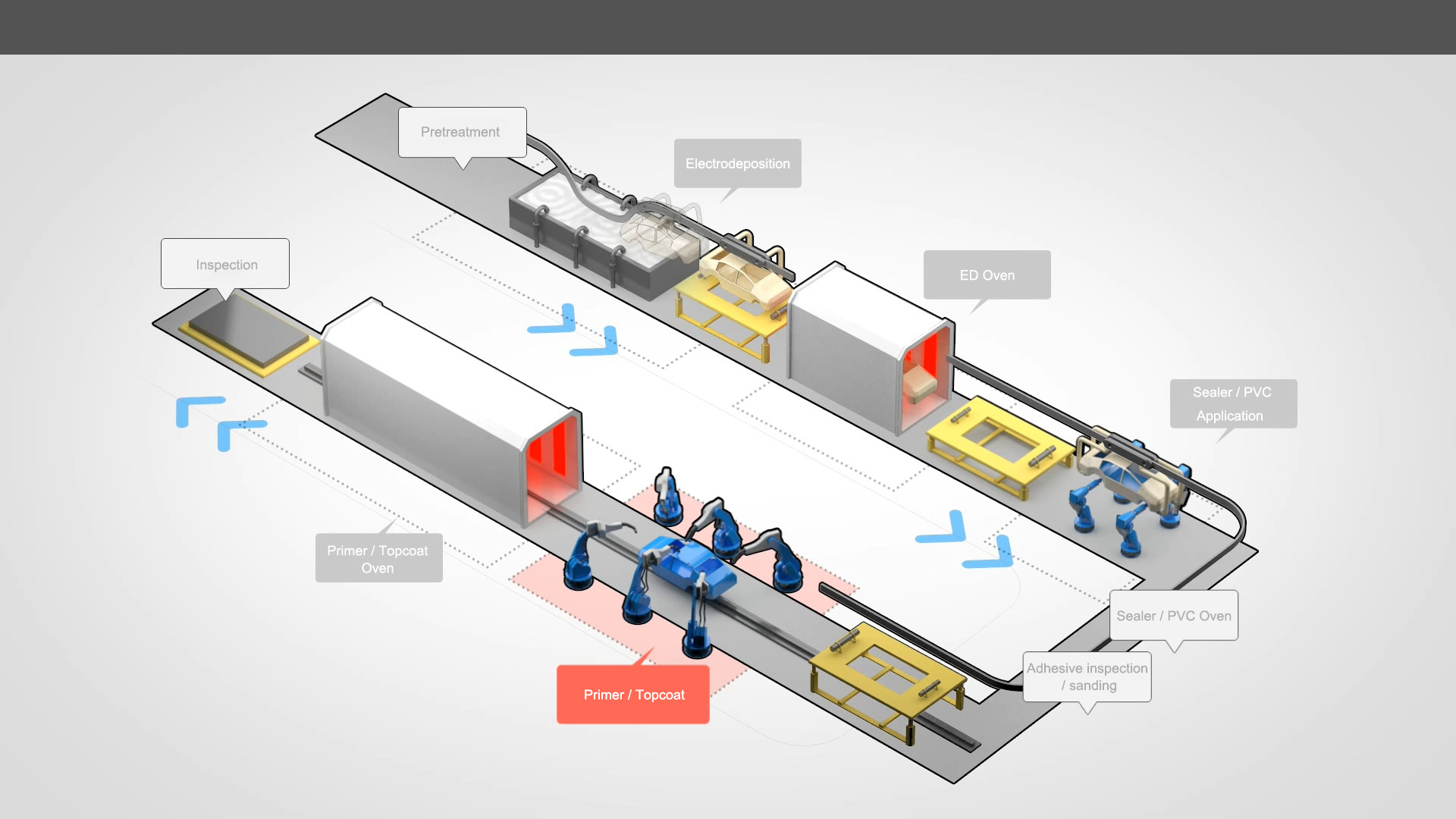

1. daawayn: Si looga saaro saliidda aan loo baahnayn, hadhaaga alxanka, iyo wasakhda dusha sare ee agabka jidhka baabuurka ee warshadda jidhka, filimka zinc phosphate (3 ~ 5)㎛) ayaa lagu dabaqaa oogada jidhka si loo kordhiyo adhesion inta lagu jiro daboolka (electrodeposition).habka.Ujeedada ilaalinta daxalka jidhka baabuurka.

Nadiifinta ka hor: Ka dib marka la isku keeno jirka, waxaa lagu dhaqaa biyo ka hor inta aan la nadiifin.

- Hoos u dhigista ugu weyn: Waxay ka saartaa saliidda jidhka baabuurka.

Biyo raaci shuruudo: Wakiilka daawaynta leh titanium oo ah qaybta ugu muhiimsan, abuurista tiro badan oo colloids ah oo ku yaal dusha birta si ay u kordhiso falcelinta samaynta filim fosfateed zinc cufan si loo soo saaro kareemyo cufan oo cufan.

-Filimka phosphate Zinc: Filimka zinc phosphate ayaa lagu dabaqaa si loo xoojiyo ku-dhejinta jaakadaha hoose iyo in la joojiyo falcelinta daxalka.

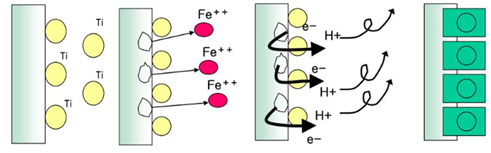

1) Etching wuxuu ka bilaabmaa qaybta anode ee xaashida birta ee xalka daahan

2) Iyadoo ku xiran daxalka hadda jira, cations ayaa lagu cunaa cathode, iyo pH ee interface-ka ayaa kor u kaca.

3) Colloid oogada sare waxay noqotaa xudunta oo dhalata

- Biyaha foornada qallalan: Habka si buuxda looga saaro qoyaanka substrate ka dib markii habka daaweynta ka hor la dhammeeyo.

※ Kala wareejinta kulaylka iyo qalajinta gacanta

Ka dib markaad jidhka ku daboosho filimka zinc phosphate ( ), ku dhaq biyo oo ku qalaji gacanta.Qalajinta gacanta lagu gooyay waa hab si buuxda looga saaro qoyaanka shayga la dahaadhay ka dibna la sameeyo habka rinjiyeynta ee soo socda.Kor u qaad heerkulka si aad u uumibaxdo qoyaanka iyada oo loo marayo wareejinta kulaylka.Qalajinta ( uumi-baxa ) waa dhacdo dhacda marka heerkulku korka adag ee xidhiidhka uu ka hooseeyo barta karkarinta iyo cadaadiska atmospheric uu ka hooseeyo cadaadiska uumiga.isbedel waji ayaa dhici doona.Heerkulka iyo wakhtiga loo baahan yahay foornada qalajinta ee gacanta lagu gooyey way kala duwan yihiin iyadoo ku xidhan walxaha, dhumucda, iyo qaabka shayga lagu dahaadhay.Caadiyan, 10 daqiiqo at 120 ~ 150 ℃ waa wax caadi ah, iyo sababta kor u qaadida heerkulka waa in la kordhiyo cadaadiska uumiga biyaha u dhigma heerkulkaas iyo in ay si degdeg ah u engegaan iyadoo la siinayo tamar kulayl badan.Waqtigaan, waa inuusan jirin isbeddel bir ah ama kiimiko ah heerkulka awgeed.

1,Habka Electrodeposition: Habka samaynta filim daahan oo ku yaala gudaha ama dibadda jidhka baabuurka adiga oo isticmaalaya electrophoresis iyada oo loo marayo koronto ka dib marka la geliyo jidhka baabuurka rinjiga korantada, ujeedada ka hortagga daxalka jidhka baabuurka

- Electrodeposition: rinjiyeynta Electrodeposition waa habka rinjiyeynta kaas oo rinjiga si koronto ah loogu dhejiyo iyada oo la dhex gelinayo jidhka baabuurka dareeraha rinjiga iyo anode ama cathode dhex qulqulaya jidhka baabuurka.Si kastaba ha ahaatee, waa hab ku habboon wax soo saarka ballaaran, wayna adagtahay in dib loo rinjiyeeyo marka filimka daahan lagu dhejiyo oo korontadu aysan socon.

- DI mayr

- Foornada Qalajinta Electrodeposition: Wixii daahan cationic electrodeposition, kuwaas oo inta badan loo isticmaalo, foornada kulaylka-qallajinta ayaa loo isticmaalaa sababtoo ah filimka la dhigay ee dusha sare waxaa lagu sifeeyaa dareeraha kulaylka by kulaylka crosslinking (daaweynta kulaylka) falcelinta.Heerkulka iyo wakhtiga loo baahan yahay kuleylku way kala duwan yihiin iyadoo ku xidhan shayga, dhumucda, iyo qaabka shayga la dahaadhay.Xaaladda shay yar oo khafiif ah, heerkulka dusha sare waa 200-210 ° C heerkulka foornada waa 210-230 ° C, iyo wakhtiga kulaylku guud ahaan waa 20-30 daqiiqo wadar ahaan 10 daqiiqo ama ka badan wakhtiga kululaynta shayga la dahaadhay iyo 200-210°C wakhtiga haynta.

- Daalidda korantada: Shiidi qaybaha qallafsan iyo kuwa soo baxay ee dusha sare si aad u noqoto mid siman.

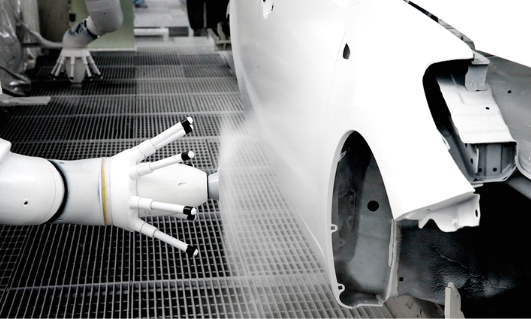

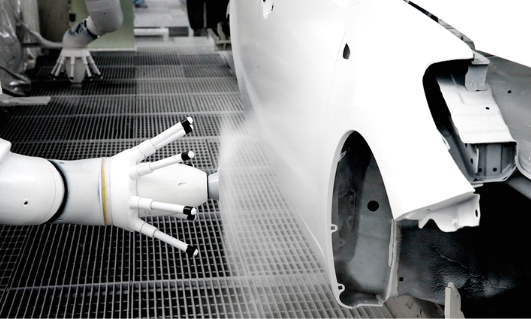

2, Rinjiga Halfway: Tani waa habka loo marsado rinjiga, kaas oo inta badan loo tixraaco sida qalab.Waxay nadiifisaa dusha sare si jaakada sare ay si fiican ugu dhegto oo ay door ka qaadato hagaajinta caabbinta daxalka.Midab yar oo kala duwan ayaan dhexda u isticmaalayaa si uu u dhigmo midabka jaakada sare.

- Habka dhexdhexaadka ah

- Foornada qallajinta dhexdhexaad ah

3. jaakad sare: Habka lagu dabaqayo midabka baabuurka muuqda iyo dhamaystirka rinjiga hufan.Dhawaan, sababtoo ah xeerarka deegaanka, iwm., rinji-saaxiibtinimo eco-saaxiibtinimo (ka kooban walxaha aan degganeyn) ayaa si tartiib tartiib ah loo isticmaalaa.Cad ka dib jaakada sare

- habka jaakada top

- foornada lagu qalajiyo dusha sare

※ Wareejinta kulaylka ee korantada/dhexda/jaakada sare kulaylinta iyo qalajinta foornada

Foornada qalajinta, kuleylka ayaa loo wareejiyaa dusha rinji laba siyaabood.

Convection: Si si fudud loo gaaro heerkulka daaweynta kulaylka ee filimka daahan, hawo degdeg ah ayaa loo baahan yahay, iyo convection xawaaraha sare waxaa la helay by wareegga hawada kulul ee foornada qalajiyo xawaaraha dabaysha sare (convection qasab ah).

Kulaylka dhalaalka ah: Darbiga ayaa lagu kululeeyaa ilaa dhowr boqol oo darajo ka sarreeya heerkulka lagu daweynayo filimka daahan ee foornada qallajinta si gaar ah, kulaylka wuxuu u gudbiyaa dusha rinji si la mid ah shooladda jidhka u diiriso.

Waqtiga boostada: Nov-08-2022